RO4003C PCB 2-Layer 8mil Cost-Effective Solution for Cellular Base Stations and Automotive Sensors

1. Introduction of RO4003C

Rogers RO4003C materials are specialized woven glass-reinforced hydrocarbon/ceramics that combine the electrical performance of PTFE/woven glass with the manufacturability of epoxy/glass. Available in various configurations, RO4003C laminates use both 1080 and 1674 glass fabric styles, ensuring all configurations meet the same electrical performance specifications.

These laminates maintain tight control over the dielectric constant (Dk) and exhibit low loss, while utilizing standard processing methods similar to epoxy/glass but at a significantly lower cost compared to traditional microwave laminates. Unlike PTFE-based materials, RO4003C does not require special through-hole treatments or handling procedures.

RO4003C materials are non-brominated and do not hold a UL 94 V-0 rating. The thermal coefficient of expansion (CTE) of RO4003C offers several advantages to circuit designers. Its expansion coefficient closely matches that of copper, providing excellent dimensional stability, essential for mixed dielectric multi-layer board constructions. The low Z-axis CTE ensures reliable plated through-hole quality, even in harsh thermal shock environments. RO4003C has a Tg exceeding 280°C (536°F), ensuring stable expansion characteristics throughout the entire range of circuit processing temperatures.

2. Features

- Dielectric Constant (Dk) of 3.38 ± 0.05 at 10 GHz

- Dissipation Factor of 0.0027 at 10 GHz and 0.0021 at 2.5 GHz

- Thermal Coefficient of Dielectric Constant of +40 ppm/°C

- Thermal Conductivity of 0.71 W/m/°K

- CTE: X axis 11 ppm/°C, Y axis 14 ppm/°C, Z axis 46 ppm/°C

- Low moisture absorption of 0.06%

3. Benefits

- Ideal for multi-layer board (MLB) constructions

- Processes similarly to FR-4 at a lower fabrication cost

- Designed for performance-sensitive, high-volume applications

- Competitively priced

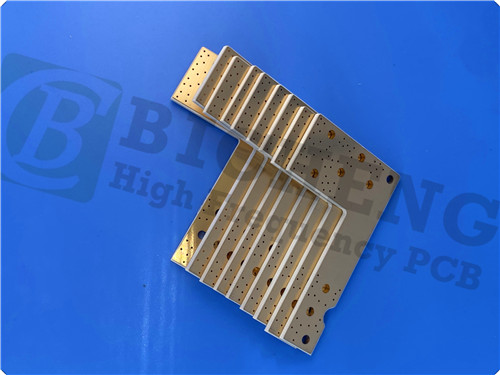

4. PCB Stackup: 2-layer rigid PCB

- Copper Layer 1: 35 µm

- Rogers 4003C Core: 0.203 mm (8 mil)

- Copper Layer 2: 35 µm

5. PCB Construction Details

- Board dimensions: 117.04 mm x 67.11 mm = 1 PCS, ± 0.15 mm

- Minimum Trace/Space: 4/4 mils

- Minimum Hole Size: 0.3 mm

- No blind vias

- Finished board thickness: 0.3 mm

- Finished copper weight: 1 oz (1.4 mils) for outer layers

- Via plating thickness: 20 µm

- Surface finish: Immersion Silver

- Top Silkscreen: Black

- Bottom Silkscreen: No

- Top Solder Mask: No

- Bottom Solder Mask: No

- 100% Electrical testing performed prior to shipment

6.PCB Statistics

- Components: 19

- Total Pads: 76

- Through Hole Pads: 45

- Top SMT Pads: 31

- Bottom SMT Pads: 0

- Vias: 67

- Nets: 2

7. Type of Artwork Supplied

Gerber RS-274-X

8. Accepted Standard

IPC-Class-2

9. Availability :Worldwide

10. Some Typical Applications

- Cellular base station antennas and power amplifiers

- RF identification tags

- Automotive radar and sensors

- Low Noise Block (LNB) for direct broadcast satellites